How Magnets are Used in the Recycling Industry

Scrap metal is one of the most recycled commodities, and magnets are an important part of metal recycling.

Recycling metal has been a common practice for centuries. The ancient Romans recycled captured bronze statues into armor and weapons. The Vikings smelted and repurposed used or broken weapons. Metal scrapyards become common in the 1920s. Airplane and automotive parts during the 1940s relied heavily on recycled metal.

Magnetic Separation of Metals

Recycling begins with separating different types of metals and alloys. Ferrous metals are metals that include iron, such as tin, steel, iron, cast iron and steel. These alloys are magnetic, so permanent magnets are used to identify these metals.

Since the 1960s, permanent magnets have been used to help separate metals in recycling plants. Magnetic separation is a simple and eco-friendly way to identify and sort metals.

Magnets attract metals containing iron, making them easy to separate. Other metals do not contain iron, so a magnet will not stick to them. Recyclable metals such as aluminum are easy to identify because they aren’t magnetic.

Magnets are also used in recycling to collect fine metallic particles on the recycling line. This helps ensure that other recycled products such as paper are free of metal contamination.

How do Permanent Magnets Work with Different Types of Magnetism?

The atomic structure of certain elements can cause the element to respond differently to a magnetic field.

Ferromagnetic metals – such as iron – are fully magnetic. They are strongly attracted magnets. We can observe this attraction visually and by feeling the pull of the magnet on the metal.

Paramagnetic metals are weakly attracted to magnets. Unlike ferromagnetic metals, they do not remain magnetic when removed from the magnetic field. Paramagnetic metals include platinum, tin, magnesium, and aluminum.

Diamagnetic metals are weakly repelled by both magnetic poles. They’re generally considered to be “non-magnetic”. Gold, silver, copper, carbon, and lead are examples of diamagnetic elements.

Each type of magnetism can indicate how long a metal will remain actively magnetic. Using this information can help recycling centers distinguish between different types of metal.

Permanent magnets are a great way to distinguish metals, as they can help distinguish metals without harming the sample. Chemical testing can sometimes require removing or damaging the sample in order to test it.

The tendency of a magnet to attract ferrous metals is still a core principle of metal sorting. Magnetic separator bars can sort metals into ferrous and nonferrous metals. Later sorting processes can go into greater detail.

Valuing Scrap Metal

The value of steel, iron, or other ferrous metals is less than that of nonferrous materials. Nonferrous metals do not contain iron. A magnet does not stick to nonferrous metals.

A permanent magnet is a small, non-destructive way for scrapyards to assess whether a sample is ferrous. This helps the estimator to more accurately assess the value of the metal.

Some common types of nonferrous metals are those made of aluminum. This includes aluminum cans, brass, copper, lead and zinc. Some metals contain both iron and a nonferrous metal. An alloy with ferrous metal will have a lower value than an alloy made entirely of nonferrous material.

The response of a magnet may also help determine whether a metal is suitable for a given application. Copper, for example, being non-ferrous, is commonly used in electrical wiring.

Magnets in Quality Control

When recycling centers begin melting down metals for recycling, it must ensure the metals are pure. Certain mixtures of metals can cause problems with recycling machines.

Magnets are used in a wide range of magnetic separators. They can even separate non-magnetic materials such as aluminum UBC’s (used beverage cans). This enables recycling companies to recover metals or remove metal from a reclaimed material.

The presence of different metals can help discover ferrous contaminants. Using a magnet can determine, for example, if there are steel screws in the aluminum. Should this be the case, the screws must be removed before the aluminum is smelted.

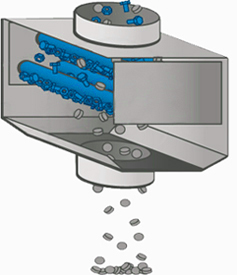

The separation of non-ferrous metals can be simplified by a machine called an Eddy Current Separator. This machine features a multi-pole, strong magnetic rotor that spins at high speed. It induces a current when aluminum enters the field. The current produces a magnetic field in the opposite direction of the rotating field. This results in a force that ejects the aluminum, pushing it away from other materials.

Magnetic Recycling in the Future

Economic and environmental interests will continue to drive an emphasis on reuse and recovery. The global metal recycling market size, which was $217 billion in 2020, is expected to exceed $368 billion by 2030.

Permanent magnets have long been used to identify and recover the ferrous metals. As new technologies continue to develop, rare earth magnets continue to play a role in recycling.