Neodymium Polymagnets

Polymagnets | Special Function Magnets

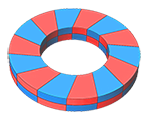

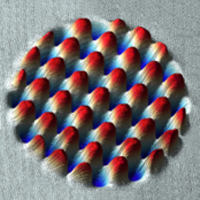

Polymagnets (Special Function Magnets) are created by magnetizing Neodymium Magnets with special magnetic field patterns. Due to these unique patterns of Maxels (Magnetic Pixels) in the magnet, they are able to have very unique features. Having a very near field attraction, they work well on thin metals. Some patterns provide excellent centering properties, while others provide rotational alignment, or even twist release functions.

Custom Polymagnets

Amazing Magnets produces high-performance custom polymagnets for a wide range of industrial uses. We can produce polymagnets for industrial design, aerospace, and automotive applications. To talk about your unique application needs, contact us to speak to a member of our team.

Phone: 512-678-4192

Email: CustomerCare@AmazingMagnets.com

Attach Polymagnets

The magnetic field of attached polymagnets is designed to be close to the surface of the magnet. This feature provides greater safety from a distance and concentrates the field making it stronger. For best results use with traction tape.

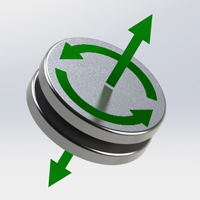

Rotational Alignment

Rotational alignment polymagnets are designed to attach together and have a rotational detent or alignment position.

Twist Release

Twist Release Polymagnets attract in one position and repel when rotated.

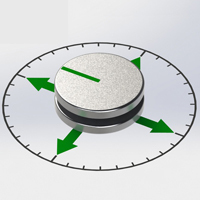

Axial Centering

Centering alignment polymagnets are designed to attach together with high shear/slide force.

Polymagnet® Kit

The polymagnet kit contains 6 different polymagnet pairs, 1 conventional magnet, 1 steel test plate, and 1 sheet of magfilm.